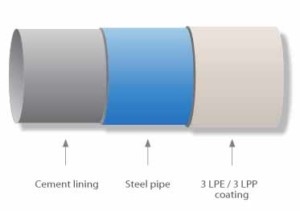

INTERNAL PROTECTIVE CEMENT LINING FOR STEEL PIPES

Product Detail :

Cement Mortar Lining of the internal surface of steel pipe are highly durable, with records showing pipes still in service after 100 years in municipal and water service life. This durability is achieved by mixing the mortar such that the pores within its structure are highly alkaline, making the lining resistant to the growth of bacteria, which can affect other types of lining.

Linings can either be cement mortar lining consisting of ordinary Portland Cement mortar, ideal for potable water, or specialist chemically resistant mortars for wastewater projects which are subject to hydrogen sulphide attack. A further decisive advantage is mortar′s self-healing property, e.g. cracks in the lining close spontaneously in non-aggressive waters

In order to achieve the required cement mortar lining quality requirements, surface preparation by internal pipe blasting equipment prior to coating is essential. A mixture of cement mortar lining supplied by the batch mixing plant is placed into the pipe and the pipe rotated at a high centrifugal force, resulting in even thickness’ of up to 1 1/4” or 32 mm, excess water is removed, and the pipe is conveyed for subsequent curing station

Besides internal pipe blasting and the actual internal cement mortar lining, plants also contain stations for prewashing, preheating, blow out (dust removal), and final curing.

Specifications taken into account when designing the cement mortar lining equipment are API 5L 44th Edition, API RP 10E, AWWA C205, DIN 2614, DIN 2880, ASTM C150, BS 1881.

The technological process of internal cement lining assures anti- corrosion protection and stability of hydraulic parameters of pipe- lines for water and sewages and allows manufacturing products that meet all the requirements demanded by customers and inter- national standards.

Applications

Steel pipes and fittings with cement lining are used for raw and potable water supply pipelines as well as for sewage system for both municipal and industrial effluents. These pipe systems assure cost effective and ecological solutions, due to material and energy saving in terms of extension of their working life and environmen- tally friendly technology. Cement lining is a process by which steel pipe and fittings are coated internally with cement mortar. This process combines the physical strength of steel with the protective qualities of cement mortar. The lining is applied centrifugally to pipe, creating a smooth finish the length of the pipe. Fittings, flanges, and special spool pieces are lined by hand.

Advantages of Cement Lined Steel Pipes and Fittings

- resistance to corrosion also in case of aggressive waters by appliation of sulphate resistant cement assures operational lifetime of product for several decades,

- full resistance to various oxidizing agents, e.g. ozone, chlorine,

- no tendency to incrustation which improves operational character of the pipeline,

- very high abrasion resistance allows high flow rate of fluids,

- full resistance of cement lining to plastic of strain of the steel pipes,

- chemical composition of the lining i.e. cement and sand as natural raw materials ensure that in contact with water the lining does not have any negative influence on human health.

Raw Material

- Portland cement/Sulphur resistant cement

- Sand

- Mixing water

- Curing compound

Benefits of Cement Lining

- Prevents internal corrosion

- Increases flow rates

- Decreases maintenance and pumping costs

- Extends the life of your pipe

- Eliminates replacement costs

- Prevents leaks

- Reduces risk of pipe failure

- Keeps potable water pure

- Eliminates discoloration and odors

- Thwarts natural leeching

Technical Data

We make cement mortar lining for steel pipes of diameters from 159 mm to 2032 mm, length from 6 m to 18 m, according to the conditions specified into the following standards:

- DIN 2614,

- DIN 2880,

- PN-EN 10298.

Thickness of Cement lining on pipes acc to DIN 2614 for Method II

Nominal Diameter | Thickness of Layers (mm) | ||

From | To | Minimum Layer | Max. Individual Layer Thk |

150 | 300 | 4 | 9 |

300 | 600 | 5 | 10 |

600 | 900 | 6 | 13 |

900 | 1200 | 8 | 15 |

1200 | 12 | 19 | |

Thickness of Cement lining on pipes acc to DIN 2614 for either Method II or Method III

Nominal Diameter | Thickness of Layers (mm) | |||

From | To | Nominal Thickness | Minimum Layer | Max. Individual Layer Thk |

300 | 5 | 3 | 10 | |

300 | 600 | 7 | 5 | 10 |

600 | 900 | 10 | 8 | 12 |

900 | 1200 | 12 | 10 | 15 |

1200 | 15 | 12 | 19 | |

SECTION 15076 – CEMENT-MORTAR LINED AND COATED (CML&C) STEEL PIPE

This Section designates the requirements for steel pipe fabrication, test in shop, installation of steel pipe, fabrication of steel sheet or plate, mill-manufactured steel pipe, bends, special pipes with outlets, pass holes, flanges and all other fittings.

Reference Standard

| AWWA C200 | Steel Water Pipe 6-inches and larger |

| AWWA C205 | Cement-mortar protective lining and coating |

| AWWA C207 | Steel Pipe Flanges |

| AWWA C210 | Coal-tar epoxy coating system for interior and exterior of steel water pipelines |

| AWWA C213 | Fusion-Bonded epoxy coating for the interior and exterior of steel water pipelines |

| AWS | Standard Qualification Procedure for Manual Welding Operators |

| ASME | Boiler and Pressure Vessel Code |

American Water Works Association – ANSI / AWWA C205-89

| ANSI / AWWA C205-89 | AWWA Standard for Cement-Mortar Lining and Coating for Steel Water Pipe – 4 IN. and Larger – Shop Applied. |

WEIGHT CHART

THEORETICAL WEIGHT PER LINEAL FOOT FOR CEMENT MORTAR LINING | |||||||

O.D. SIZE | THICKNESS | THICKNESS | THICKNESS | THICKNESS | THICKNESS | THICKNESS | THICKNESS |

1/4″ | 5/16″ | 3/8″ | 1/2″ | 5/8″ | 3/4″ | 1″ | |

POUNDS PER LINEAL FOOT | |||||||

3.500″ | 2.66 | ||||||

4.500″ | 3.42 | 4.20 | |||||

6.625″ | 5.18 | 6.41 | 7.61 | ||||

8.625″ | 6.83 | 8.48 | 10.09 | ||||

10.75″ | 8.59 | 10.68 | 12.73 | ||||

12.750″ | 10.25 | 12.75 | 15.22 | 20.08 | |||

15.250″ | 12.94 | 16.11 | 19.25 | 25.46 | 31.57 | 37.57 | 48.85 |

17.375″ | 15.59 | 18.18 | 21.74 | 28.77 | 35.71 | 42.54 | 55.48 |

19.781″ | 20.70 | 24.06 | 31.88 | 39.59 | 47.20 | 62.10 | |

21.781″ | 22.77 | 26.55 | 35.19 | 43.73 | 52.16 | 68.72 | |

25.750″ | 31.52 | 41.81 | 52.01 | 52.10 | 81.97 | ||

31.875″ | 38.64 | 51.75 | 64.43 | 77.00 | 101.84 | ||

37.875″ | 45.92 | 61.69 | 76.85 | 91.90 | 121.71 | ||

43.875″ | 71.56 | 89.18 | 106.69 | 141.39 | |||

49.875″ | 81.56 | 99.18 | 116.69 | 151.39 | |||

AWWA C205 CEMENT MORTAR LINING THICKNESS | ||||

| PIPE SIZE | 4″ TO 10″ | 11″ TO 23″ | 24″ TO 36″ | OVER 36″ |

| COATING THICKNESS | 1/4″ | 5/16″ | 3/8″ | 1/2″ |

Lining Tolerance is +1/8″ – 1/16″

THEORETICAL WEIGHTS PER LINEAL FOOT FOR CEMENT MORTAR COATING | ||||||

O.D. SIZE | THICKNESS | THICKNESS | THICKNESS | THICKNESS | THICKNESS | THICKNESS |

1/2″ | 3/8″ | 3/4″ | 1″ | 1 1/2″ | 1 1/4″ | |

POUNDS PER LINEAL FOOT | ||||||

3.500″ | 6.44 | 8.25 | 10.14 | 14.17 | 18.51 | 23.18 |

4.500″ | 8.28 | 10.61 | 13.04 | 18.22 | 23.81 | 29.81 |

6.625″ | 11.80 | 15.01 | 18.32 | 25.26 | 32.61 | 40.36 |

8.625″ | 15.11 | 19.15 | 23.29 | 31.88 | 40.88 | 50.30 |

10.75″ | 18.63 | 23.55 | 28.57 | 38.92 | 49.68 | 60.86 |

12.750″ | 21.94 | 27.69 | 33.54 | 45.54 | 57.96 | 70.78 |

15.250″ | 34.42 | 41.61 | 56.30 | 71.42 | 86.91 | |

17.375″ | 38.56 | 46.58 | 62.93 | 79.70 | 96.97 | |

19.781″ | 42.70 | 51.55 | 69.55 | 87.98 | 106.83 | |

21.781″ | 56.51 | 76.17 | 96.26 | 116.70 | ||

25.750″ | 66.45 | 89.48 | 112.81 | 136.62 | ||

31.875″ | 81.35 | 109.29 | 137.65 | 166.42 | ||

37.875″ | 96.26 | 129.16 | 162.49 | 196.21 | ||

43.875″ | 111.25 | 149.19 | 187.58 | 226.42 | ||

49.875″ | 126.03 | 163.97 | 202.36 | 241.20 | ||

AWWA C205 CEMENT MORTAR COATING THICKNESS | |||

| PIPE SIZE | 4″ TO 12″ | 13″ TO 19″ | Over 19″ |

| COATING THICKNESS | 3/4″ | 3/4″ | 3/4″ |

Coating Tolerance is +1/8″ – 0

Due to AWWA C205 tolerances, weights are approximate

Nominal Diameter | AWWA Pipe Size (O.D.) | |

4″ | 4 1/2″ | (4.500) |

6″ | 6 5/8″ | (6.625) |

8″ | 8 5/8″ | (8.625) |

10″ | 10 3/4″ | (10.750) |

12″ | 12 3/4″ | (12.750) |

14″ | 15 1/4″ | (15.250) |

16″ | 17 3/8″ | (17.375) |

18″ | 19 25/32″ | (19.781) |

20″ | 21 25/32″ | (21.781) |

24″ | 35 3/4″ | (25.750) |

30″ | 31 7/8″ | (31.875) |

36″ | 37 7/8″ | (37.875.) |

40″ | 41 7/8″ | (41.875) |

42″ | 43 7/8″ | (43.875) |

48″ | 49 7/8″ | (49.875) |

Nominal I.D. sizes refer to Cement Lined Pipe

Export Destinations of our Sleeves

| MIDDLE EAST » Saudi Arabia | AFRICA » Nigeria NORTH AMERICA » Usa | EUROPE » Russia | ASIA » India SOUTH AMERICA » Argentina |