INTERNAL PIPELINE COATING

Product Detail :

Why Internal Coating ?

Oil and gas fluids contain solid particulates such as sodium chloride, potassium chloride, other salts, carbonates, sulfates, partially polymerized oils, including waxes and paraffins as well as dirt and greases. Some of these particulates dissolve in the fluid while some remain in suspension. Traveling through pipelines at speeds approaching 200 mph, these particulates become aggressively corrosive projectiles. Coatings designed for internal pipeline application must be engineered to withstand the high impact created by these fast moving particulates.

- It is providing constant protection against corrosion and abrasion caused by the fluid through a uniform physical barrier.

- Prevents corrosion of the material throughout the cycle, storage, commissioning, operation and stops.

- Increases the production rate.

- Control of deposition of paraffins, asphaltenes and fouling materials.

- Improved hydraulic system efficiency (reduction of friction coefficient) thus increasing the transport capacity of the system fluid.

- Lower production costs by pumping (investment pays for itself in less than three years).

- Reduced maintenance costs (pigging and inhibitors).

Internal Pipe Coatings have been designed to protect the internal surfaces of (steel) pipe against corrosion as well as provide flow enhancement.

Internal diameter (ID) coatings are used to improve the flow of gas through the pipeline by creating a smooth defect free surface greatly increasing the flow of gas through the pipeline.

Advantages

- Suitable for fresh and salt water immersion

- Effective for speeding up production

- Suitable for corrosive environments

- Resistant to many solvents and chemicals

- Resistant to cathodic disbondment

- Increased pipeline flow,

- Reduced energy costs,

- Reduced use of inhibitors,

- Reduced maintenance,

- Reduced pig runs and wear,

- Clean product delivery,

- Increased pipeline life, and

- Rapid return on investment.

- Protects steel pipelines being stored for extended periods prior to installation

- Reduces the cost of inhibitors and pigging

- Eliminates the formation of black powder and inhibits microorganism growth activity

- Extends the life of the pipeline

- Provides excellent corrosion protection (chemical/water)

- Enhances flow assurance

- Greatly reduces pipe cost when compared to using high alloy pipe

- All applied coatings shall meet drinking water standards. Contact Bayou for additional information regarding certification to the NSF/ANSI Standard 61.

- Offers better visual inspection with a smooth, hard surface

- You can use pipes and fittings smaller thicknesses (Schedules), since it is not necessary to design with safety margins lost by corrosion.

- It facilitates inspection and commissioning.

- Extends the life of the material.

- Different coatings for different applications and operating conditions.

- Quick return on investment.

-

It represents lower investment costs compared with steel alloys greater

Alloy steel

Cost driver

Naked Carbon Steel 100% (base cost)

Carbon steel lining 150%

Stainless steel 316L 600%

Stainless steel 904L 900%

Inconel 625 1800%

Inconel 825 2200%

WHAT ARE THE COATINGS?

They are applied to change substrate properties (corrosion resistance, abrasion, adhesion, conductivity, etc.) materials Technologies:

| Liquids |

Epoxy Phenolic – Epoxy Urethanes |

| Powder |

FBE (fusion bonded epoxy) – Fluoro polymers – Nylon |

| Others |

Chemical deposition |

Important factors in the application of coatings:

-

-

- Surface Preparation

- Application controlled conditions (% RH, ° T)

-

Types of Coating :

Cement Lining

Cement mortar lining (CML) is a centrifugally-applied continuous lining of dense Portland cement mortar with a smooth and uniform finish. These products were developed to provide an economical form of internal corrosion and abrasion protection for oilfield tubulars and line pipe. CML is used primarily in water injection and disposal lines. These products are also suitable for potable water lines but should not be specified for lines where hammer conditions or fluid pH below six (acidic condition) exist.

The lining provides economical and lasting protection against the corrosive effects of saline solutions and other types of industrial liquids and wastes. It has excellent structural and spall-resistant properties.

This is a proven technology with over a century of use in municipal water mains and water service lines. The system is compatible with other external coatings. Extruded polyethylene external coating may be applied over CML pipe provided the steel is not heated rapidly by more than 80°C during the coating process. Cement is alkaline in contact with water which reduces the corrosion impact to the metal substrate under the cement mortar. Cement mortar however has restrictions with regards to water fluid speeds and reduces the pipe ID to a larger extent than FBE coating systems would. Cement also has a higher surface roughness compared to FBE and promotes microbiological growth to a larger extent, furthermore the degree of flexibility of cement mortar lined pipe and impact resistance is inferior to FBE type of linings.

Fusion Bonded Epoxy

Typically when fusion bonded epoxy (FBE) is referenced, it is assumed to be for the external protection of line pipe. There are a wide array of FBEs, primed and unprimed, that have proven to be successful in the area of corrosion protection, hydraulic improvement and deposit mitigation for the internal of line pipe. FBE is a plant-applied thermoset lining for steel pipes where internal corrosion protection or a smooth surface is required. This lining reduces friction costs and compression costs, and provides a clean internal surface along with corrosion protection. As with internal plastic coatings, FBE has been used since the early 1960s. FBE coatings are used extensively in the oil and gas industry for the coating of line pipe, valves, fittings and for downhole materials such as tubing and casing. The fusion bonded epoxy coating systems are applied at what is called the “cladding temperature” of the powder. The cladding temperature is the point at which the powder will melt and flow allowing it to adhere to the preprepared (grit-blasted and/or thermal-cleaned surfaces). Powder coating systems are applied in a one layer process as opposed to liquid coating systems which can be applied in numerous, thin layers with an intermediate drying/baking cycle between each layer. As opposed to cement linings, FBEs are thick film coatings usually with a Dry Film Thickness (DFT) of less than 400 microns. Advantages of FBE coatings are their adhesive properties, their chemical resistance, their high degree of flexibility and good impact resistance. Drawbacks of FBE coating systems are the high degree of surface preparation required for their application as well as a curing temperature in excess of 200°C, all of which requires ‘shop applied’ coating application.

It is an epoxy powder coating adhesion by fusion (Fusion Bonded Epoxy – FBE), industry standard, environmentally safe, heat-stable, and widely used as corrosion protection of pipe and fittings system FBE coating consists of applying a resin termodirigida, applied in thickness of 400 – 600 microns on the surface Epoxy. The film exhibits an extermely hard smooth surface with excellent adhesion to the steel surface, excellent chemical resistance, high strength the efforts of the terrain making it a lasting and reliable coating.

Uses

The FBE anticorrosion coating is widely used for the protection of pipes, fittings and equipment steel transmission and distribution networks of the oil products sector. Likewise it has wide application in other sectors such as mining, agribusiness, construction, etc.

Advantages of Using Internal Coatings FUSION BONDED EPOXY (FBE)

-

-

- Durability and high performance under different conditions (proven over 50 years)

- It works perfectly with cathodic protection systems

- Film with high density of links (high cross-linked film)

- High impact resistance

- High abrasion resistance

- High flexibility

- Short times of application and curing

- Environmentally friendly (does not contain VOC)

- FBE cure time is typically less than a minute.

- The quality and integrity of the anti-corrosion coating is maintained throughout the pipeline.

- Requires no mixing.

- An automated application reduces the risk of human error.

- Optimum coating in all soil types.

- FBE girth welds are very cost effective, especially over larger projects.

- Little to no waste product for every girth weld.

-

Testing

Abrasive Characterization

-

-

- Fineness

- Hardness

- Density

- Specific Gravity

- Conductivity

-

Surface Preparation

-

-

- Measurement of environmental conditions (T °, RH, dew point)

- Anchoring profile

- Sales in quantifying Substrate

- Readiness Assessment: Brush Off, Commercial, Near White Metal, Metal White, Manual, Mechanic

-

Covering

| Visual Inspection |

|

| Measurement of Dry Film Thickness |

|

| Measurement of adhesion to steel |

|

| Adherence measurement Existing Coating |

|

| Measurement Method Tape Adhesion |

|

| Hardness test |

|

| Abrasion resistance |

|

| Tensile Strength |

|

| Thermal Resistance |

|

| Electrical detection of discontinuities (Holiday High and Low) |

|

| Flexibility |

|

| Performance Assessment Salina House |

|

All tests were conducted under ASTM, SSPC, CSA, NACE, ISO standards, among others.

Polyamide Coatings

Internal coatings based on polyamide chemistry are defined as thermoplastics. Unlike thermoset materials, thermoplastics do not undergo a final curing step at elevated temperatures. Instead, these materials are applied at very high temperatures and are then led through a controlled cool down process that will vary depending on the type of polyamide and the desired final properties. Due to this, heatresistant polyamide powder coatings are primarily plant-applied coating systems. Polyamide coatings have advantages over FBE coating materials due to a higher degree of flexibility and less damage experienced from mechanical impact. Polyamide coatings generally require a liquid epoxy or phenolic primer in order to ensure good adhesion.

Flow Efficiency Coating

Flow efficiency coatings (FEC) are thin film epoxy coatings applied in natural gas pipelines to smooth the internal pipe surface for improved flow. Application of FEC replaces the internal rough surface of a steel pipe with a smooth surface finish which reduces friction and turbulence to increase flow efficiency. This may allow for use of a smaller diameter pipe or lower compression requirements resulting in reduced capital and operating costs. After application of FEC, the clean internal surface of the pipe provides corrosion protection prior to installation and allows for easier visual inspection. The cleaner surface reduces the cost and effort of drying the pipe after hydrostatic testing.

Anti-Corrosion for Potable Water – Epoxy Lining

One type of internal coating system for potable water applications is a 100% solids, two component, and solvent free, high build epoxy lining used to provide corrosion protection for the internals of steel pipes in potable water applications. BS6920 and ANSI/NSF 61 are local standards for potable water, and can also be used for other applications including raw water, process water, sewage, wastewater, crude oil, and white oils. These standards usually call for testing of the applied coating material with regards to taste, smell, microbiological growth and possible leaching out of heavy metals and/or solvents. Coatings used for potable water handling must be solvent free in an applied form and are used on valves, fittings, tanks and elbows as well.

These products are designed for high build, single coat applications by airless spray equipment.

Performance Properties

These products are allowed to cure to form a hard and glossy surface film with excellent resistance for a wide range of aqueous chemicals including potable water, effluents, raw water, process water, sewage, crude oils, and white oils. These products exhibit excellent adhesion on correctly-prepared steel surfaces. They are compatible with most readily-available field joint coating systems such as heatshrinkable sleeves, liquid epoxy, FBE and polyurethane coatings.

Easy Application

These products are suitable for application as a single coat system, using both standard and/or plural component airless spray equipment. They are capable of being applied by roller or brush for small applications and repairs.

Environmentally Safe

With a 100% by volume solids, zero volatile organic compound (VOC) formulation, these products are designed to meet strict health, safety and environmental standards. They eliminate solvent emissions, explosion risk and fire hazard and are designed to eliminate the risk of solvent retention which can influence water quality and coating defects.

Anti-Corrosion for Potable Water – FBE Powder Coatings

Another type of internal coating is the FBE system. FBE powder coatings have been used in the pipeline industry for more than 40 years. These powder coatings contain no solvents and are 100 % solid without any dangerous raw materials.

FBE powder coatings meet a lot of standards around the world like DIN/ISO/EN, GSK, AWWA and drinking water approvals such as

-

-

-

- UBA-Guideline, Germany

- ACS, France

- WRAS, United Kingdom

- KIWA, Netherlands

- Belgaqua, Belgium

- NSF 61, USA

-

-

The purity of the water for human consumption is the highest priority for the companies involved in the supply chain of manufacture and management of the mains distribution systems. Therefor the control of the products used in the industry must also be of the utmost importance.

In Europe the control of materials used is normally determined through government departments or independent test institutes or a combination of both. In certain cases only raw materials that are on a “positive” list can be used in a fusion bonded epoxy formulation. In this case the powder manufacturer would also be audited on a regular basis and samples taken from production of FBE products to confirm they continue to meet the approval documentation.

In the case of the KIWA or NSF drinking water approval the control of raw materials is very strict, with the chemical composition of individual raw materials assessed to ensure the products conform to their requirements.

In addition to these regulations further testing is performed on the growth of microorganisms on materials intended for use in drinking water. In particular the FBE technology has been tested in Germany by the Hygiene-Institut des Ruhrgebiets for examination and assessment following the regulations of the DVGW (German Association of Gas and Water) technical rules, method W 270. The test is targeted at determining any signs of bactericidal or fungicidal properties of the FBE-coated surface. The FBE technology has been tested to and meets the requirements of this specification with documentation available.

Anti-Corrosion for Potable Water – Polyurethane Lining

Polyurethane-based products are 100% solids, either one or two component systems, 1:1 mixed by volume, high performance, high build, fast set, aromatic and rigid polyurethane lining. They have been specifically designed as corrosion and abrasion resistant coating for long term protection of water pipe internals. They should comply with the requirements of NSF/ANSI 61 standard for potable water and AWWA C222 standard. They can also be used for other applications including raw water, process water, sewage, and wastewater.

Excellent Performance Properties

Polyurethane based systems cure to form a very hard and tough surface film with excellent resistance to abrasion, impact, chemical attack, and cathodic disbondment. They exhibit excellent adhesion on correctly-prepared steel and ductile iron surfaces. The application of a primer is not necessary. They are compatible with most readily available field joint coating systems such as heat-shrinkable sleeves, liquid epoxy, FBE, and polyurethane coatings.

All Temperature Cure and Unlimited Film Build

PU can be cured at almost any ambient temperature. These products have a very fast curing time and are therefore applied using plural component spray equipment. The unlimited film build can be achieved in a single coat multi-pass application. The end result is a thick, impervious, and holiday-free internal coating film within minutes of spray application. Inspection and quality testing can be made within 30 minutes and pipes can be put into service within hours.

Environmentally Safe

PU is a 100% solids system, being free of solvents and VOCs, and is designed to meet strict health, safety and environmental standards. The product contains only pure resins and the finished coating is safe for drinking water and food contact.

Liquid Epoxy Coating

Epoxy coating system is preferred for lining pipe internal surfaces for potable water pipelines in order to protect steel surface from corrosion. Equally, thru the use of alimentary grade epoxies, the properties of water is maintained safe and healthy for the use in household.

Epoxy is again widely used as internal lining in oil & gas sector in order to reduce friction and save energy for long pipeline projects.

Special grade of liquid epoxy is also applied for gas pipes in order to reduce the back pressure created by roughness of the internal pipe surface. Application of this type of epoxy reduces energy costs related with transportation of natural gas.

Plant Pipe Coating

The most common types of plant–applied coatings are:

• Epoxy coating — is available in either “thin film” or double layer

• Three–layer coating

• Hot Tape coatings — include the use of heat shrink tape

• Cold Tape coatings

• Hot Enamel coatings

Yard Pipe Coating

Some of the above coating systems may be applied in a yard environment. Most suitable are:

• Hot Tape coatings

• Liquid coatings

• Cold Tape coating

• Hot Enamel coatings

Field Pipe Coating (“over–the–ditch”)

• Cold Tape coatings — various types are available for special conditions such as high–shear resistance or high temperature resistance

• Hot Tape coatings — a line travel only

Field Joint Protection

• Cold PVC or PE Tape coatings

• Liquid coatings — these range from coal tar polyurethane to urethane to epoxy

• Heat Shrink Sleeves — the most widely used form of joint protection available

Coating Rehabilitation

• Cold Tape coatings

• Liquid coatings

Problem :

Internal coated pipelines had a wide variety of application but have one major back fall of protecting internal weld joints. The internal coated pipes are joined through welding hence they have an internal cut-back portion of 1 to 2 inches. The cut back portion in the pipes is due to the heat generated during the welding. The welding heat burns the internal coating upto 1 to 2 inches. Corrosion starts from the uncoated portion. Coating the uncoated portion after welding process is a costly and timely affair. It takes heavy robotics engineering & sophisticated machinery to resolve such problems.

Solutions :

Until recently, pipes with internal plant coating did not have a wide area of application. This was due to the difficulty of adequately internally protecting welded joints and creating homogenous conditions for transporting the product.

The problem of internal protection of weld joints has only recently been solved in practice. Which increases the service life of the pipeline (by up to 25 years).

The Solution is RELI SLEEVE (pipe / insert sleeve.)

Export Destinations of our Sleeves

| MIDDLE EAST

» Saudi Arabia |

AFRICA

» Nigeria NORTH AMERICA » Usa |

EUROPE

» Russia |

ASIA

» India SOUTH AMERICA » Argentina |

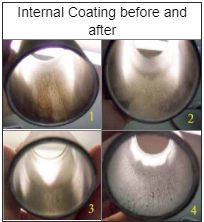

Internal Coating Process Flowchart